Views: 0 Author: Site Editor Publish Time: 2025-11-04 Origin: Site

With laser precision, solve wear-resistance challenges. From October 28 to 31, 2025, the 21st China International Coal Mining Technology Exchange and Equipment Exhibition was grandly held at the China International Exhibition Center in Beijing. As a pioneer and trailblazer in ceramic 3D printing technology and a provider of wear-resistant solutions, Hengpu Laser made a wonderful appearance with a series of innovative achievements, offering high-quality wear-resistant solutions for fields such as mining equipment, construction machinery, and metallurgical equipment.

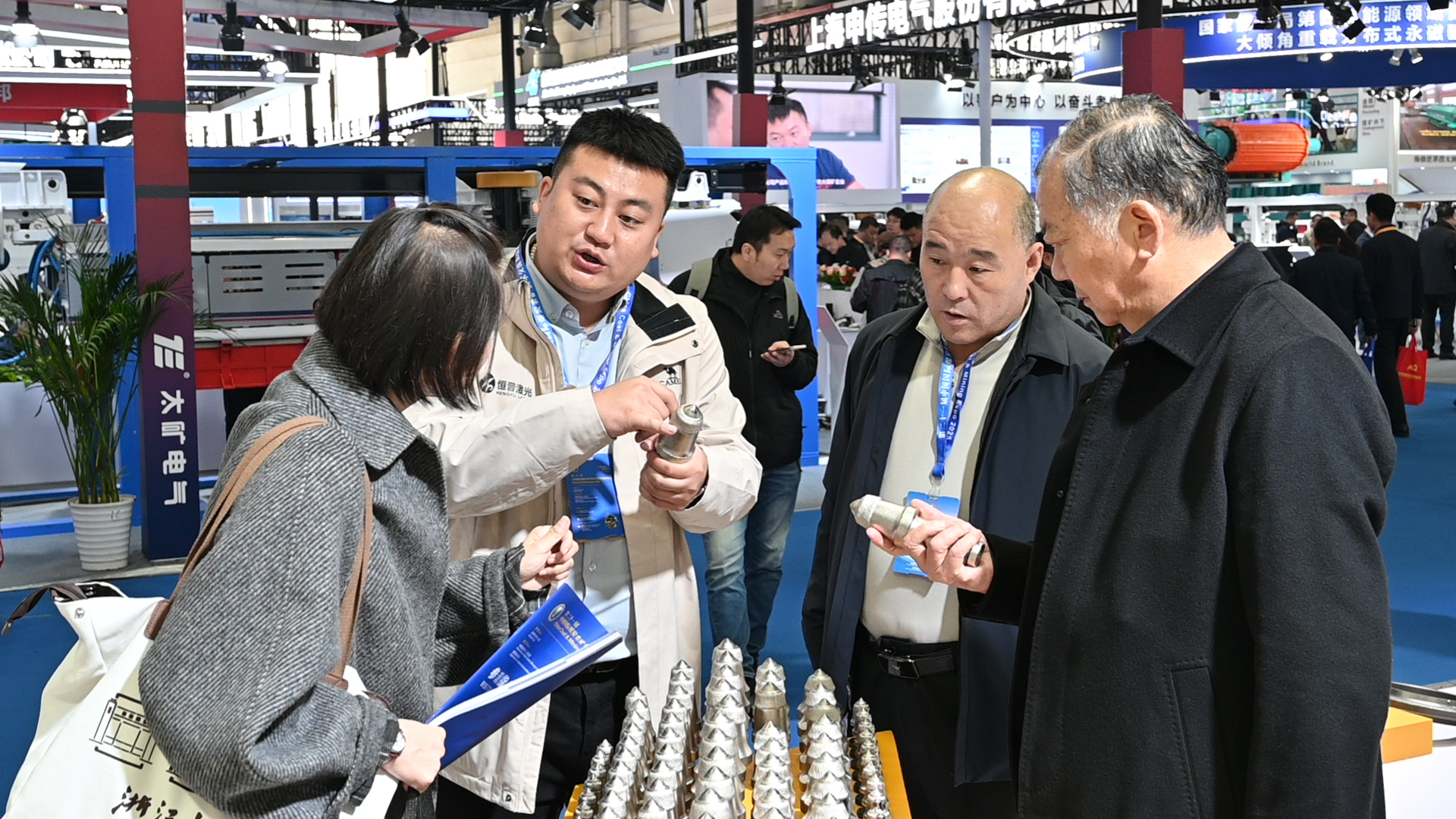

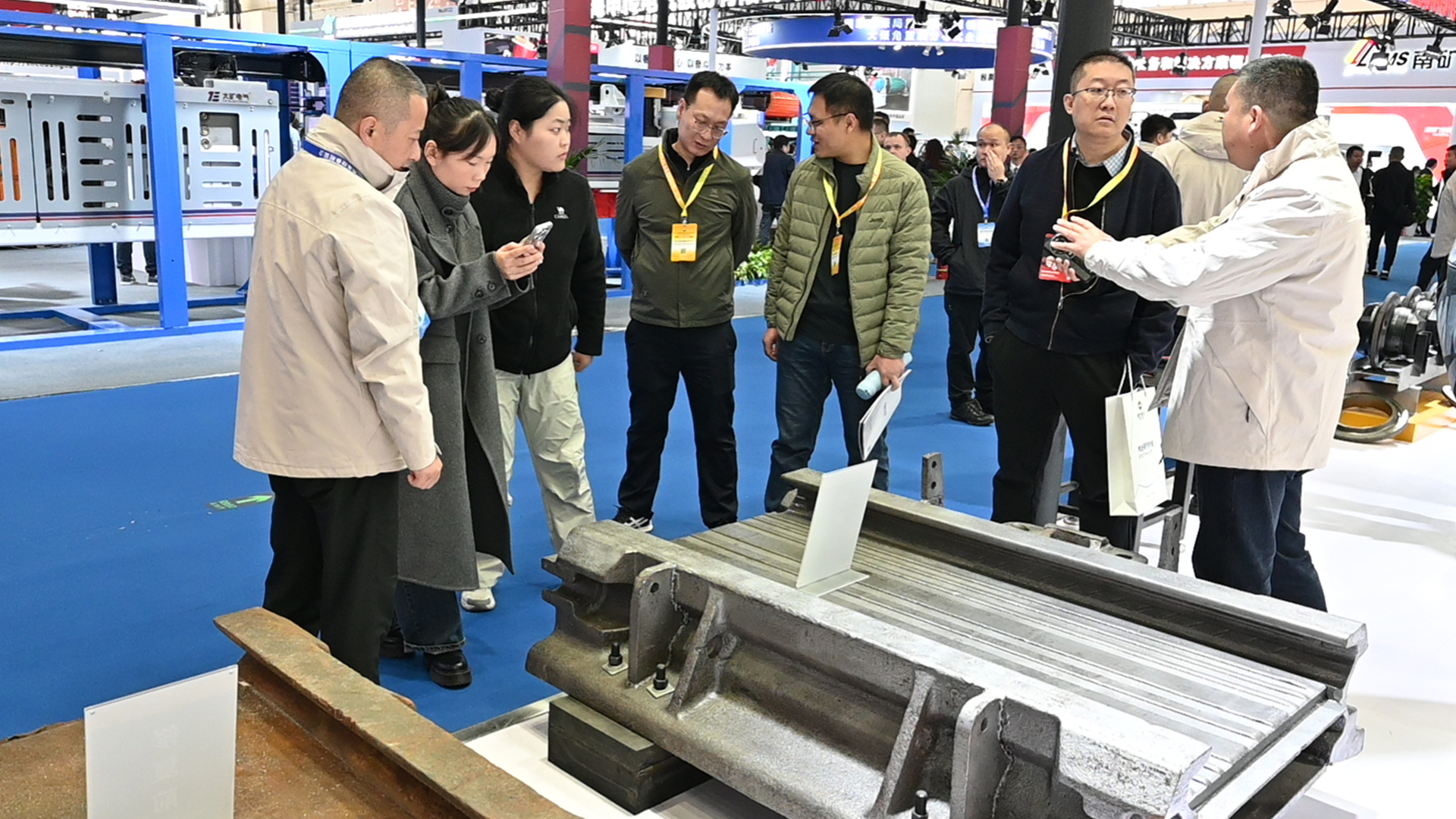

At the exhibition site, Hengpu Laser attracted numerous new and old customers as well as industry experts to stop and conduct in-depth exchanges with its innovative technologies and products including cutting picks, wear-resistant blocks, scraper conveyor middle troughs, and polycrystalline diamond (PCD) compact drill bits.

The independently developed 3D laser-implanted ceramic particle technology by Hengpu Laser breaks through the metal-ceramic atomic bonding method, perfectly integrating the metal matrix with ceramic materials. It overcomes the technical bottleneck of traditional wear-resistant materials—"high hardness but easy to brittle fracture, strong toughness but not wear-resistant"—and is innovatively applied to various key industrial wear-resistant scenarios, showing significant advantages in wear resistance, service life, and comprehensive cost.

The company's 3D printing brand "Hengpu Cutting Picks" continues to strive to set an industry benchmark, providing customers with high-quality cutting pick products with superior performance and strong working condition adaptability. A variety of cutting picks with rich types and wide applications were displayed at the booth, vividly demonstrating the technical characteristics of Hengpu Cutting Picks in laser implantation, bionic structure design, cemented carbide, and wear resistance.

Hengpu Laser's laser-implanted ceramic wear-resistant blocks (strips/plates) innovatively integrate 3D printing technology with high-performance super wear-resistant ceramic materials. They fundamentally solve the problem of easy detachment in traditional overlay welding processes, significantly improving wear resistance and reliability.

Hengpu Laser's remanufacturing process for mining scraper conveyor middle troughs not only performs laser strengthening on key parts such as the middle plate and bottom plate but also remanufactures middle troughs with no repair value, "turning waste into treasure". The performance of the remanufactured products is comparable to that of new ones, providing long-life and high-stability core component solutions for mining, coal transportation, and other scenarios, effectively helping enterprises reduce costs, increase efficiency, save energy, and reduce emissions.

Founded in 2013, Hengpu (Ningbo) Laser Technology Co., Ltd. adheres to the business philosophy of "Walk with Light, Persevere for Distant Horizons". It is committed to solving the wear problems of metal parts and building a brand with global influence. In the future, the company will continue to deepen its focus on the wear-resistant field, strengthen technological R&D and product iteration, empower industrial manufacturing, boost various industries, and unlock the infinite potential of laser 3D printing!